Why Choose Hose

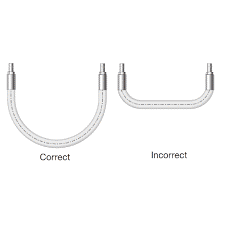

When using a rigid material like pipe, it must be installed either straight or as a series of angels cut to exact lengths. Compound directions involve more exact lengths and numerous connections, and every connection is a potential leak point.

Hose, on the other hand, perfectly lends itself to bending and routing. Its inherent flexibility means that it will require only end connectors, not one for every directional shift.

And how does having fewer connections benefit the system owner?

- Material and labor costs are lowered

- Leakage risk is reduced

- Chance of pressure drop is minimized

- Possibility of media being entrapped is less

Yet another advantage of hose over rigid materials is that hose can compensate for small discrepancies in distances between connection points, so long as bend radiuses are properly maintained.

Often in system design tweaks are necessary. Hose can mean less scrap in those situations.

Finally, hose can add to simplicity in cleaning and maintenance. They can easily be removed or replaced, and, when coiled, hoses fit inside sterilization equipment. Rigid materials of any significant length exceed the capabilities of most cleaning equipment tanks.

When designing a fluid system, consider the safety advantages and cost reductions possible from the use of flexible hose.

Safe Product Selection

The complete catalog contents must be reviewed to ensure that the system designer and user make a safe product selection. When selecting products, the total system design must be considered to ensure safe, trouble-free performance. Function, material compatibility, adequate ratings, proper installation, operation, and maintenance are the responsibilities of the system designer and user.

Hose, on the other hand, perfectly lends itself to bending and routing. Its inherent flexibility means that it will require only end connectors, not one for every directional shift.