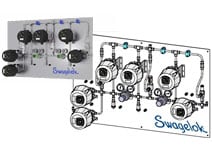

Swagelok Southern California can build that for you

We build the fluid systems so you can deliver the results.

The quality you've come to expect from Swagelok® products is available for the complete systems and configurations. Our local assembly and fabrication team in Southern California is comprised of Swagelok-certified integrators and field engineers with expertise in building assemblies using high quality components. We have the skill to incorporate third party products, pumps, automation and more to meet your needs...bring us a challenge. Whether you need to bend pipe, assemble fittings, part to part connections or deliver an army of panels, compare our resources to going it alone. One bill of materials, one part number and a local team to rely on.

Draw from local expertise to include:

- P&ID optimization and creation of CAD drawings

- Custom hose fabrication, including crimped hose assembly

- Gas panel, skid, cart assembly

High volume CNC tube bending or manual tube bending

- Orbital welding

- Fitting, threaded fitting and valve assembly

- Setting proportional relief valves

- High pressure testing (from 10,000 to 60,000psig)

- Class 100 cleanroom is used for assembly and packaging

- Cleaning capabilities now accommodate IEST specifications

- Leak and bubble testing (Snoop or Immersion)

- Industrial liquid filling of pressure gauges

- Hydraulic pre-swaging

- Custom tagging, labeling, and kitting

Every Swagelok custom solution is backed by the Swagelok Limited Lifetime Warranty, with the technical support that critical applications have relied on since 1947. Where requested or required, testing to guarantee the system and full traceability and mill certification can be provided. Every item is also professionally packaged and delivered with care.

Application Highlights

Here are examples of the types of assemblies and results that are available from Swagelok Southern California's custom assembly and fabrication team. The list of what we can do is extensive, including sample systems, gas distribution and changeover manifolds as well as these examples:

|

|

|

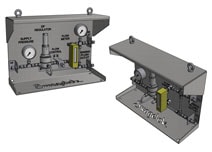

Continuous Purge Panel SystemWhen continuous purge of a barrier fluid is required or fluids are being measured, consider Swagelok for locally built systems, optimized for your application. |

H2 Refueling Priority PanelsTo manage and detect receiver pressure and dispenser filling sequence for refueling systems, Swagelok custom panels ensure reliability and safety at the station. |

H2 PEM Electrolyzer Sub-AssembliesProton Exchange Membrane is the most effective water electrolysis technology. Sub-assemblies can be built locally using Swagelok products and services for long life and reliability. |

|

|

|

Fill CartsSafely and efficiently maintain the barrier fluid in your seal pots while the system is online and in operation to increase pump time with a Swagelok fill cart. Units are customizable. |

Ammonia SamplerExpedite the sampling process with Swagelok's ammonia sampler with consistency while increasing safety by minimizing exposure to liquid and vaporized ammonia. |