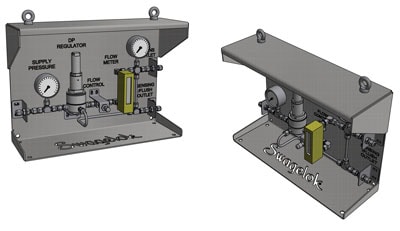

Continuous Purge Systems

Swagelok® Custom Solutions can build systems for use in plants where a continuous purge of a barrier fluid is required or fluids are being measured. These are Continuous Purge Systems (CPS).

What is a continuous purge system?

The level of process fluid in a tank or vessel is a fundamental measurement required for safe and optimal process control. Although there are a variety of methods to measure these fluids, there are some applications where the severe nature of either the process conditions themselves or the operating environment poses problems for conventional approaches. A continuous purge system is designed to provide a barrier fluid through an impulse line, irrespective of forward or back pressures within the system.

This approach allows fluid measurement to be performed while keeping sensitive measuring instruments away from the harsh or hazardous environment, improving both reliability and uptime in severe service applications.

A CPS may also be referred to as a bubbler system.

Where are they used?

If you work with water treatment, processing, and environmental applications you may have come across one of these systems:

- Slurry/Viscous fluid flow and pressure measurements

- Dirty gas flow and pressure measurements

- Loading arm rotating joint pressure barrier

- Pressurized flushing stem seals on hazardous fluids

- Catalyst slide valve flushing

- Tidal height measurement

- Compressor seals / compressor dry gas seal panels

- Flushing ring support

Swagelok Key Design Features

- Modular design

- Standardization

- Easily adjustable (anti-tamper available on request)

- Robust design suitable for all external environments

- Flexible supply pressure, 4 to 400 barg

- Wide flow capability (0.5l/min to 33,000 l/min)

- Wide range of material options

What issues can a continuous purge system resolve?

These field-tested designs ensure optimum system performance and can help resolve the following:

- Impulse line plugging

- Trapped bubbles/gas pockets in liquid impulse lines (wet legs)

- Trapped liquids in gas impulse lines (dry legs)

- Temperature induced measurement errors

- Damage due to process and ambient temperature

- Instrument sensing element corrosion

- Hazardous area installations (ATEX)

- Lack of electrical supply

The CPS panel will provide a consistent flow of purge gas or liquid irrespective of upstream pressure and without affecting the pressure. This is useful on applications where the impulse line can clog due to process contaminants, barrier fluid is required for material compatibility against corrosion or where cool flushing fluid is required to protect the transmitters and valves from heat.

For level measurements, the benefits are:

- Full mechanical system

- ATEX compliant

- It is not affected by surface foam, vapors, turbulence within the tank, high temperatures, and solid contents

Possible Implications of Plugged Impulse Lines

- Reduced reliability of pressure measurement

- Loss of measurement accuracy

- Slower instrument response to pressure variations

- Total loss of process condition visibility

- Unsafe acts intended to circumvent the problem during operation (inhibitation, alarm masking, uncontrolled modifications, rodding, etc)

Ready to Learn More?

As always, our assemblies are proudly backed by our Swagelok Limited Lifetime Warranty. If you encounter any questions or issues with the system, Swagelok Southern California provides the local support to move you forward.