Know Your Stainless Steel

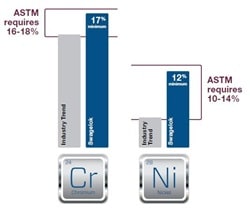

The percentages of both elements can vary, even while maintaining ASTM standards.

Swagelok considers the midpoint of the standard to be the minimum requirement in the stainless steel it uses, a requirement that maximizes performance over the the life of the fitting.

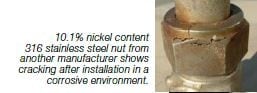

Lower levels of either element can cause parts to fail. The cracked nut below, from another manufacturer, was 316 steel with only a 10.1% nickel content that failed after installation in a corrosive environment.

Swagelok ensures these higher levels by buying only from approved mills. Control over everything, from the elevated alloy chemistry to the inspection steps that are used to during validation, is in place. The bar stock is unique to Swagelok only. It cannot be purchased by anyone else, as Swagelok buys the complete stock.

Our testing is extensive and includes 100% ultrasonic analysis (to detect abnormalities) as well as eddy current testing (to detect cracks). What this means to you is greater uniformity of the raw materials, allowing uniform manufacturability of all our components.

Although the design of the fitting is instrumental in its success, never forget the importance of the raw material bar stock.