Medium Pressure Products

FK Series vs Cone and Thread Connection

Our patented FK series medium-pressure tube fitting provides reliable, leak-tight performance specifically for these high-vibration environments. Looking to maintain your cone and thread system? Swagelok carries a range of options in various alloys and sizes up to 1½ inches, and anti-vibration options to help ensure a leak-tight system.

The FK series creates strong, reliable connections faster — even in high-risk, high-vibration environments. Swagelok delivers high-quality performance when the pressure is at its highest.

The FK Series Advantage

The FK improves uptime during startup and then throughout the life of the asset. It shortens commissioning time as it seals upon initial makeup, the first time. Once operational, uptime is improved as the FK series fittings have excellent performance in applications that have vibration.

The following benefits combine to deliver a lower total lifecycle cost of ownership:

Reduces Installation Cost

- Installs approximately 5x faster than cone and thread connections

- Requires common tools, simple assembly methods, and minimal training

- Features preassembled cartridge for rapid error-proof assembly

Improves uptime

- Shortens initial commissioning time with no leaks at startup

- Reduces unplanned maintenance with no leaks during use

- Provide reliable performance in dynamic (vibrating) systems

Boosts safety and environmental compliance

- Avoids environmental noncompliance and costs with leak-tight design

- Offers proven reliability, with more than 100,000 connections installed

Concerns with Cone and Thread Connections

Cone and thread fittings can have a high rework rate during initial installation. After assembly, it is not uncommon to have fittings leak during initial high pressure hydrotesting. The additional tightening and/or replacement of fittings adds time to the acceptance testing. Once operational, fittings that are installed without antivibration glands are highly susceptible to leaks from vibration. This can cause constant preventative maintenance at least — and safety/environmental issues at most.

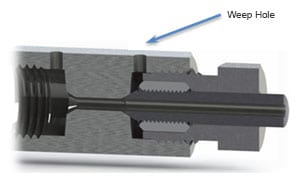

Also, the weep hole can collect chlorides if the fitting is installed in an offshore/nearshore marine environment. The chlorides can concentrate over time and initiate corrosion, which ultimately reduces the life span of the equipment.

The following contribute to the the high lifecycle cost of cone and thread fittings:

Installation

- Calls for special equipment and cutting oil

- Requires skilled and experienced labor

- Poses installation challenges - heavy-wall tubing and rework

Reliability of fittings

- Initial installation can create opportunity for leaks

- Vibration can jeopardize reliability or necessitate maintenance

- Antivibration options add cost to systems

Corrosion resistance

- The weep hole acts as a collection site for chlorides

How Does It Work?

The FK Series fitting:

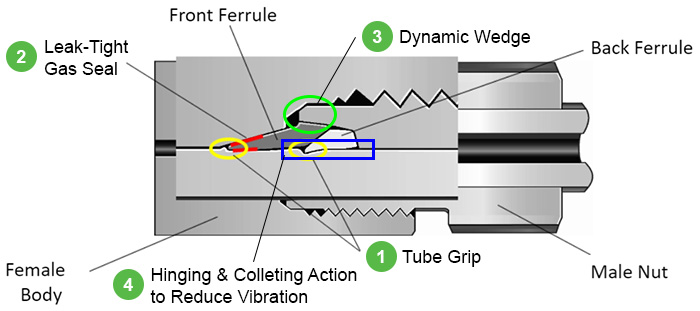

- Creates a strong tube grip with twin grip action in two areas.

- Has a better gas seal with burnishing action.

- Is designed with a dynamic wedge that provides reliable assembly that is gaugeable and can be reassembled.

- Technology includes patented low-temperature case hardening processing of the ferrules, plus the specially designed ferrule geometry, that reduces damaging effects of system dynamics with a patented hinging-colleting™ action, creating vibration resistance.

Swagelok's FK Series fitting ships as a preassembled cartridge, which prevents inverted or missing ferrules. This ensures correct ferrule and nut orientation and proper installation into the body. It's strain-hardened stainless steel body offers a lightweight, space-saving design.

Industries for Application

- Aerospace

- Chemical / Petrochemical

- Oil & Gas

- Power

- Paper & Pulp

The complete solution includes valves with FK connections:

- Ball Valve (FKB Series)

- Needle Valve (IPT Series)

- Check Valve (IPT Series)

- Relief Valve (IPT Series)

- Double Block and Bleed (IPT Series)

- Medium-Pressure Tubing (FK Series) & Medium- and High-Pressure Tubing Cone & Thread Tubing (IPT Series)

Fittings

Eliminate downtime due to leaks with the safe, reliable, efficient leak-tight protection of Swagelok fittings.

FK Medium-Pressure Gaugeable Tube Fittings and Adapter Fittings

Easy to install, the simple two-piece design of the Swagelok medium-pressure tube fittings and adapters offers a leak-tight gas seal and vibration resistance in applications up to 20,000 psig (1378 bar), with proven performance on a variety of tubing types and materials.

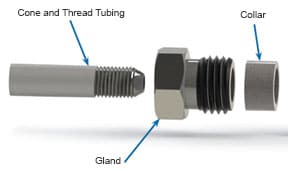

Cone & Thread Fittings

Medium pressure for up to 20,000 psig; high pressure for up to 60,000 psig maximum working pressure. Strain-hardened 316 stainless steel supplied complete with gland and collars. NACE-compliant materials and anti-vibration connection components are available to increase the dependability of your system.

Valves

Maximize the performance and reliability of your fittings with matching fluid system components designed to handle the pressure of your operation.

Ball Valves

Swagelok ball valves offer quarter-turn operation in a compact design, providing positive shutoff in applications up to 20,000 psig. Subsea service ball valves are also available in a range of sizes and connection types, including NACE-compliant for sour gas applications.

The advanced design of the FKB Series ball valve reduces seal wear and improves the reliability of connections across a full range of operating pressures and temperatures. Its trunnion-style ball with direct-load design delivers leak-tight performance, and a bottom-loaded stem design eliminates stem blowout to ensure operator safety.

Check Valves

Available in three designs to fit a variety of applications: ball-seal poppet, soft-seal poppet, and dual-seal ball. In C&T/NPT and tube fitting connections, it handles a maximum working pressure of up to 60,000 psig; nominal crack pressure of 15 psig (1 bar).

Single/Double Block & Bleed Valves

Reduce your system footprint and achieve positive isolation with single block and bleed valve (needle/needle) or double block and bleed valve (ball/needle/ball or needle/needle/ needle) options. Double block and bleed configuration allows for double positive isolation. Vee stem valve.

Needle Valves

Six body styles available with cone and thread, tube fitting, and NPT end connections, plus solutions to handle maximum working pressures of up to 60,000 psig. The non-rotating, two-piece stem assembled NVT design needle valves fully open in just four to five turns. The NVT design also allows for easy panel mounting with an integral bonnet locking mechanism to prevent accidental disassembly.

Relief Valves

Maximum working pressure of up to 20,000 psig; proportional lift design available customer adjustable or factory set. Opens gradually as the pressure increases. Choice of set or adjustable pressure operation.

Tubing

Optimize your system performance with medium- and high-pressure tubing from Swagelok — your single, trusted source for all medium- and high-pressure components.

Medium-Pressure Tubing

Put it all together with heavy-wall annealed or cold-drawn, 1/8 hard tubing. With increased material strength that allows for reduced wall thickness and enhanced flow through the same diameter tube, this is the perfect match for Swagelok medium-pressure gaugeable tube fitting and adapter fittings. And it handles the pressure (up to 20,000 psig) your operation brings to it.

Medium- and High-Pressure Cone & Thread Tubing

Need a tubing solution for a high-pressure application? Medium- and high-pressure cone and thread tubing provides a maximum working pressure of up to 60,000 psig and is readily available in various lengths. Custom lengths and pre-coned and threaded tube nipples are also available.

Training, Tools, and Accessories

Complete your assembly capabilities with tools and accessories, no matter the connection type integrated within your system. For purchase or for rent, Swagelok Los Angeles has the resources for you. We also offer Swagelok certified training to help ensure your assemblies are built for optimum operation and to safety standards.

Ensure optimal and easy installation of our FK fittings with these convenient tools:

- Preswaging Tool

- Depth Marking Tool

- Multihead Hydraulic Swaging Unit (MHSU)

- Medium-Pressure Gap Inspection Gauge

For More Information

For more information on Swagelok medium-pressure solutions, please contact Swagelok Los Angeles at (800) 252-7087 and speak to one of our customer service representatives or ask to be connected to your account manager. You can also send us an email or download our brochure.